Description

Unilin XT CW T&G Cavity Wall PIR Insulation 1200 x 450 x 90mm

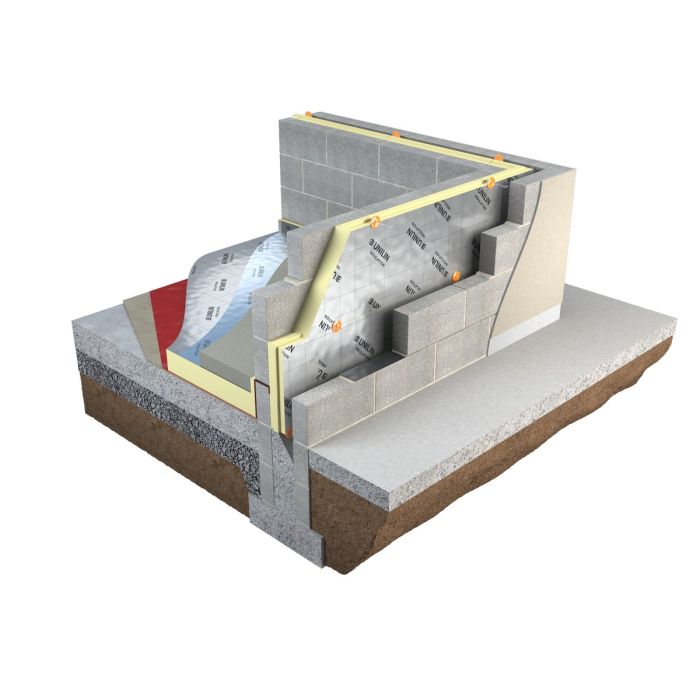

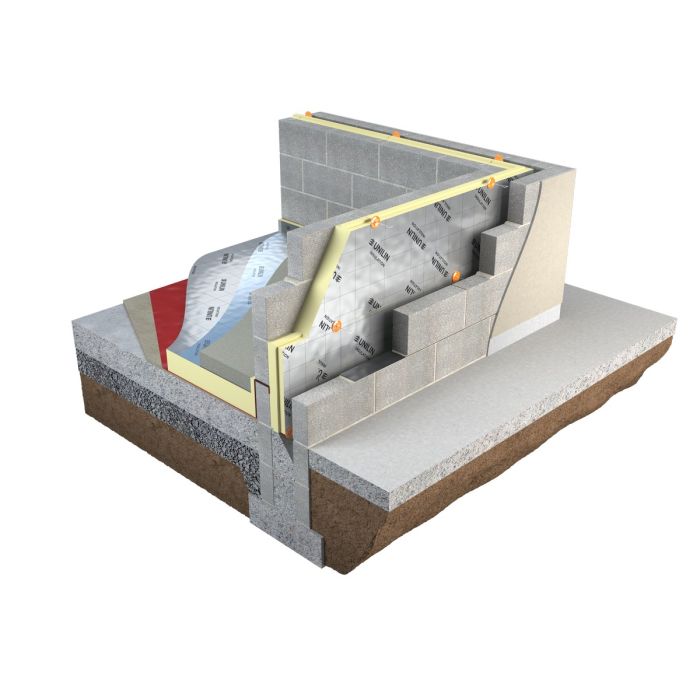

The Unilin XT CW T&G Cavity Wall PIR Insulation Board 1200 x 450 x 90mm is a high-performance thermal insulation solution designed for use in partial-fill masonry cavity walls. With tongue and groove (T&G) edges for a tight fit and reduced thermal bridging, it delivers excellent energy efficiency and long-term durability.

Manufactured from rigid polyisocyanurate (PIR) foam, this board provides superior insulation performance while maintaining a thin profile, making it ideal for new builds and renovation projects where cavity space is limited.

Features and Specifications

- Brand: Unilin Insulation

- Product Type: XT CW T&G PIR Cavity Wall Insulation Board

- Dimensions: 1200mm (L) x 450mm (W) x 90mm (T)

- Material: Rigid PIR foam core

- Thermal Conductivity: 0.022 W/mK

- Edge Profile: Tongue & Groove (T&G) for improved fit and reduced air gaps

- Facing: Low emissivity foil facings for enhanced thermal resistance

- Application: Partial-fill masonry cavity walls

Benefits

- Outstanding thermal performance – achieves low U-values with minimal thickness.

- Easy installation – lightweight and precision-engineered with T&G joints.

- Moisture-resistant – prevents water ingress and maintains insulation efficiency.

- Durable construction – retains shape and performance over time.

- Energy-saving solution – reduces heat loss and supports compliance with building regulations.

Ideal For

- New build and refurbishment projects

- Residential and commercial cavity wall insulation

- Applications where space-saving thermal efficiency is required

What is the advantage of the T&G edge design on Unilin XT CW boards?

The tongue and groove edges ensure a snug fit between boards, minimizing thermal bridging and air gaps for improved insulation performance.